Welcome to Shandong Xiangguang Abrasives Co., LTD

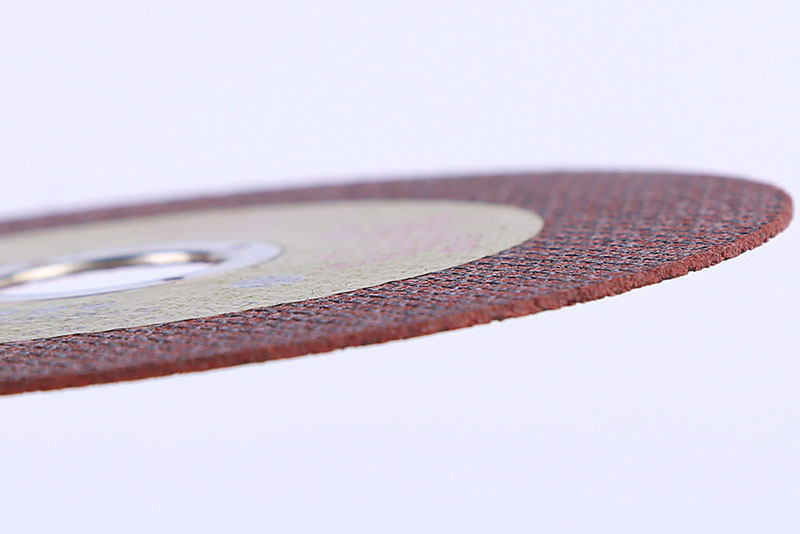

How to maintain ceramic grinding wheels

Sep 25,2024

When using it, it is important to pay attention to maintenance and upkeep, as it can last for a longer period of time. So, let's learn about its maintenance methods.

Grinding wheel is a relatively precise product, and if there are missing marks, it cannot be used. When using it, it is important to pay attention to maintenance and upkeep, as it can last for a longer period of time. So, let's learn about its maintenance methods.

① It should be noted that the inner diameter correction and positioning hole processing of ceramic grinding wheels must be carried out by the factory. If the processing is poor, it will affect the effectiveness of the product and may cause danger. The principle of enlarging the hole should not exceed the original hole diameter by 20mm to avoid affecting the balance of stress.

② If the sharpness of the grinding wheel decreases and the cutting surface becomes rough, timely grinding should be carried out. But during grinding, the original angle cannot be changed, nor can the dynamic balance be disrupted.

③ When the produced grinding wheel is not immediately used, it should be placed flat or hung up using the inner hole. Other items or feet should not be stacked on the flat saw blade, and attention should be paid to moisture and rust prevention.

④ Keep the machine clean, as any debris can also cause scratches on the grinding wheel. This is something to be aware of in daily life.

In short, the daily maintenance and upkeep of ceramic grinding wheels should be taken seriously, which will also extend their lifespan compared to before.