Welcome to Shandong Xiangguang Abrasives Co., LTD

What is the current development status of high-quality ceramic grinding wheels

Sep 25,2024

Due to factors such as difficulty in combining ceramic binders with diamond abrasives, the development and production of ceramic binder diamond grinding wheels have been hindered.

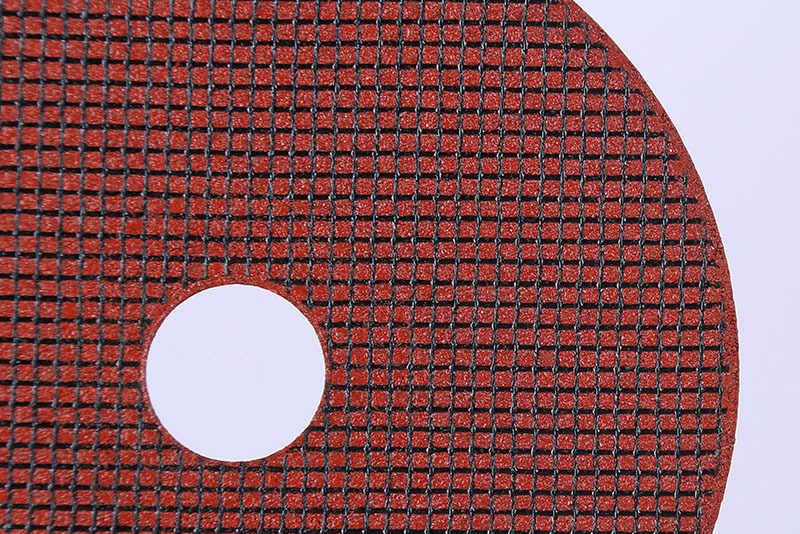

High quality ceramic grinding wheels have high strength, good heat resistance, sharp cutting, high grinding efficiency, are not easily heated or blocked during the grinding process, have small thermal expansion, and can control machining accuracy. Compared with resin bonded grinding wheels, resin bonded diamond grinding wheels solve problems such as low service life, low grinding efficiency, and the variability of the grinding tool itself during the grinding process.

As early as the 1990s, Japanese researchers studied the selection requirements for high-efficiency and high-precision grinding of ceramic bonded diamond grinding wheels, such as wheel concentration and abrasive grain requirements. Study the grinding performance of superhard material grinding wheels based on borosilicate glass binder Na2O-B2O3-SiO2 as the basic component; The formula of ceramic binder is mainly based on chemical composition, and boron glass or boron lead glass system is selected as the theoretical research object.

In foreign research, studies have begun on toughening and strengthening ceramic binders, such as microcrystallizing the glass phase of the binder and adding appropriate amounts of whiskers to the binder. They found that adding borosilicate whiskers to the binder can suppress the formation of calcite and prevent the grinding wheel from cracking due to the rapid expansion of calcite at 100 ℃ to 200 ℃; On the other hand, aluminum borate whiskers themselves can play a role in whisker reinforcement, thereby improving the tensile strength of the binder.

Due to factors such as difficulty in combining ceramic binders with diamond abrasives, the development and production of ceramic binder diamond grinding wheels have been hindered. Engineers have led the production of ceramic bonded diamond grinding wheels for gemstone grinding in China, and have developed various wheel specifications, which have gained popularity in the field of gemstone processing. The series of ceramic bonded diamond grinding wheels currently developed for grinding PCD/PCBN cutting tools, ceramic bonded diamond grinding wheels for grinding diamond composite sheets, and other series of ceramic bonded diamond grinding wheels have gained a good reputation in the market.